If the hydraulic, lubricating, compressor or gear oil you use is not made of a water base in

formulation

, then water is considered a contaminant and must be recognized and managed.

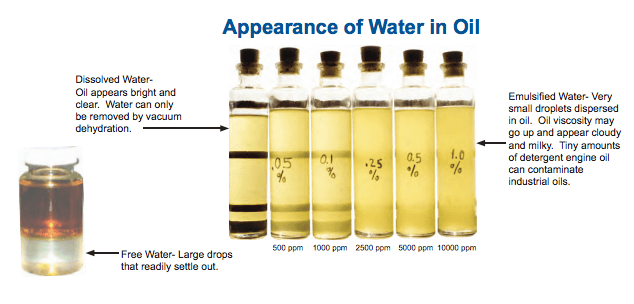

There are three types of water in a typical system: free water

,

emulsified water and dissolved water. The water saturation point of most oil, that point above which water is in a free form, is 200-400ppm, depending on age and condition.

Using 100ppm for an upper water limit for most systems using mineral base oils, this means all free and emulsified water and a significant portion of dissolved water must be removed.

A vacuum dehydrator is one of the very few methods to remove dissolved water from oil. Let's take a look at these three types of water in your system. It will give you a solid foundation for how the vacuum dehydrator works in the end.