2 min read

Factory Side Chat Podcast, Episode 9, Reducing the Total Cost of Ownership with a Kidney Loop or Offline Filtration unit

By Hy-Pro Marketing on Fri, Aug. 26, 2022

Topics: fluid cleanliness ISO Fluid Cleanliness Codes cleanliness hydraulic oil Podcast Factoryside Chat Podcast cutdirtcutcosts kidney loop

1 min read

Hy-Pro Vac-U-Dry Vacuum Dehydrator (VUD) Explainer Video

By Hy-Pro Marketing on Tue, Jul. 26, 2022

Contamination is Complicated; Removing it is Easy

Check out our latest product explainer video on Hy-Pro's VUD

The optimized balance between heat, vacuum, process design, and an easy, user-friendly operating system for removal of water and particulate from hydraulic and high viscosity lubricating oils. Equipped with generously sized, high-efficiency filtration, the VUD is the ultimate oil purifier. Keeping fluids clean and dry extends component and bearing life, increases productivity, minimizes downtime, and extends useful fluid life. The VUD is ideal for removing all forms of water, including free, emulsified, and dissolved water and gas from hydraulic and lubricating oils.

Topics: contamination fluid cleanliness vacuum dehydration vacuum dehydrator fluid contamination VUD cutdirtcutcosts hypro

2 min read

Factory Side Chat Podcast, Episode 8, Partners for Life

By Hy-Pro Marketing on Thu, Jun. 02, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: fluid cleanliness cleanliness hydraulic oil filter elements Podcast Factoryside Chat Podcast cutdirtcutcosts partners for life

1 min read

Download the Contamination Tool Mobile App

By Brad Bainbridge on Thu, Feb. 04, 2016

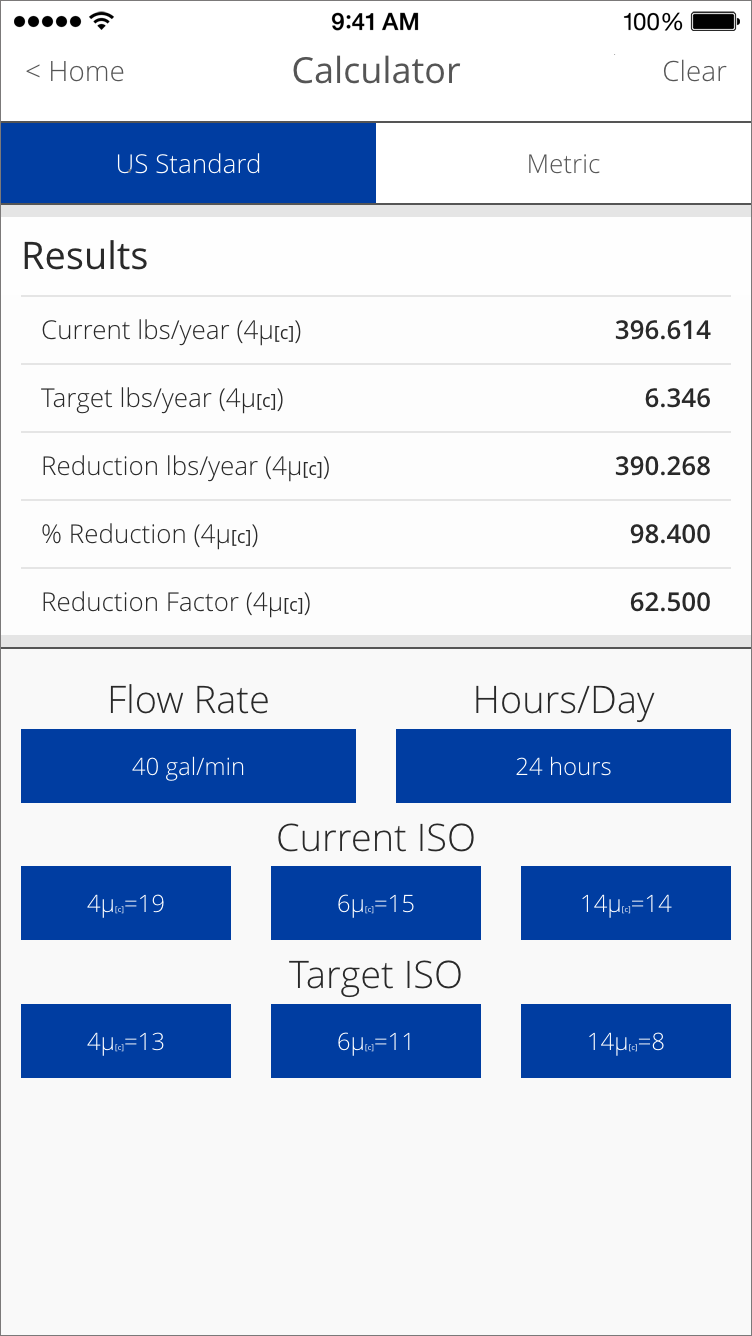

Have you downloaded our mobile app? It's an essential tool that allows you to calculate contamination levels even if you're away from your desk. All you need is your phone and this app!

The Hy-Pro Filtration Contamination Tool is now available for download on your iPhone or Android.

What can you do with Hy-Pro Contamination Tool mobile app?

With the mobile app, you'll be able to:

-

Calculate the amount of contamination passing through system components annually by specifying current flow rate, daily hours of operation and ISO fluid cleanliness code.