2 min read

Expanding the distribution of our Podcast; Apple Podcasts, Spotify, and PodBean

By Hy-Pro Marketing on Tue, Oct. 12, 2021

Topics: iso cleanliness codes DFE contaminination Podcast ISO 23369 Factoryside Chat Podcast

3 min read

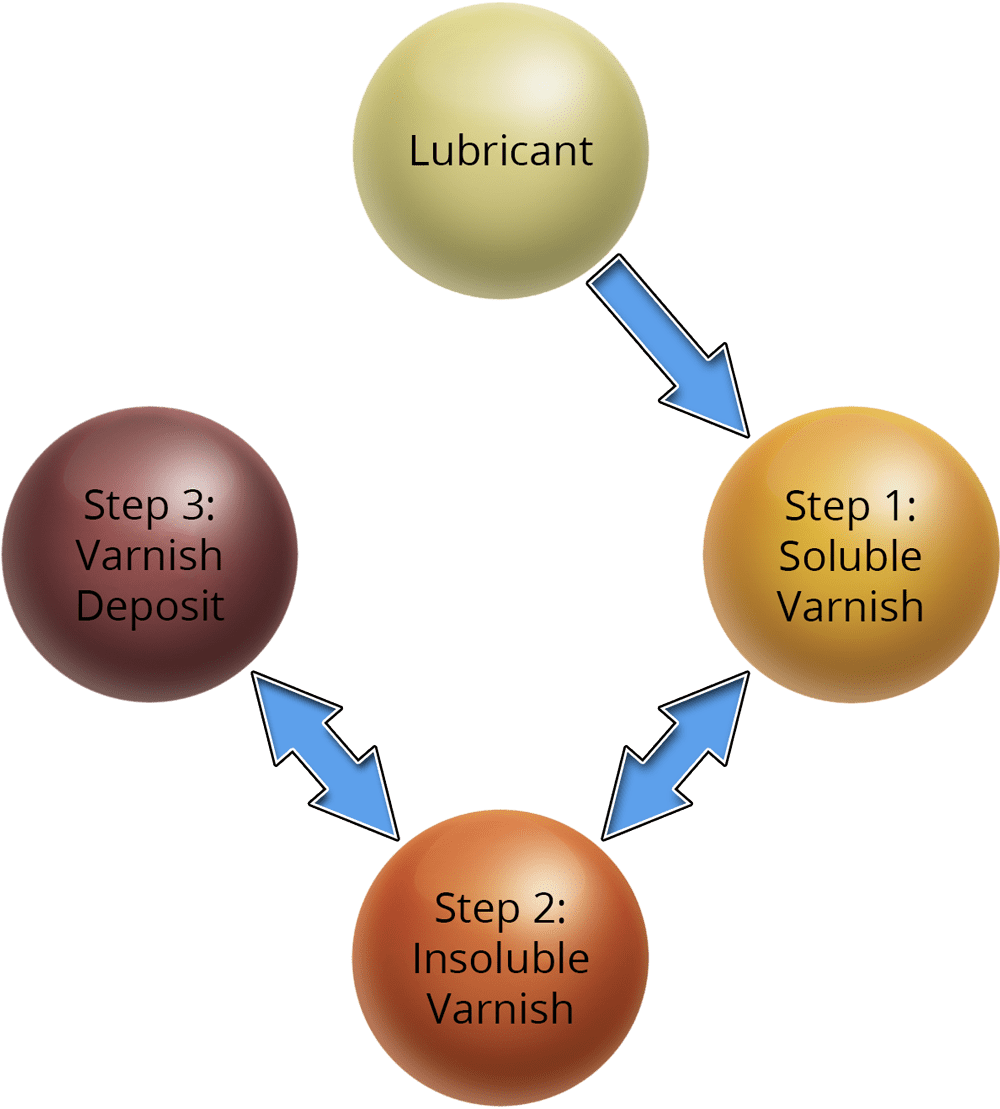

Varnish in Turbine Oil Systems

By Aaron Hoeg on Wed, Oct. 06, 2021

Despite thousands of dollars and hours spent trying to mitigate the effects of varnish in turbine oil, many still suffer from this ongoing yet solvable issue. When combustion and steam turbines fall victim to unit trip or fail-to-start conditions, varnish is the usual suspect.

Topics: water Water Contamination varnish SVR contaminination turbine oil

3 min read

Getting to Know Demulsibility

By Brad Bainbridge on Thu, Mar. 25, 2021

Demulsibility

What is Demulsibility?

Demulsibility is the ability of oil to separate from water. Oil and water naturally separate because like molecules attract each other. Oil sticks with oil, water sticks with water. Oil is "hydrophobic", or "afraid of water," which is a benefit when it comes to fluids like turbine oil.

Topics: varnish in hydraulic oil varnish in turbine oil contamination water in oil dirt Phosphate Ester diesel engine maintenance steel mills vacuum dehydration rolling mill lubricating oil filter housing sizing micro-dieseling thermal event ISO 4406 vacuum dehydrator fluid samples oil analysis metal analysis paper mill hydraulic pump samples COD duplex low-pressure gearbox contaminination hydraulic duplex high-pressure cellulose media filter elements filter comparison aluminum refinery lab

1 min read

Removing Water from Diesel; Hy-Pro's Coalescing Technology

By Brad Bainbridge on Wed, Mar. 25, 2020

In this Video we provide a brief description and demonstration of Hy-Pro's signature coalescing technology found in our FCLCOD and COT model lines.

Topics: filters coalesce technology fuel cleanliness COD video contaminination turbine oil

7 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 4 of 4

By Brad Bainbridge on Wed, Nov. 05, 2014

Combined Cycle Journal recently published an article on turbine lube oil varnish written by Peter Dufresne Jr. and his team at EPT. We’ve divided the article into four blogs to make it easier to digest -- click here to find parts one, two and three.

Topics: case study varnish SVR hydraulic oil contaminination lube oil turbine oil

4 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 3 of 4

By Brad Bainbridge on Mon, Aug. 04, 2014

Combined Cycle Journal recently published an article on turbine lube oil varnish written by Peter Dufresne Jr. and his team at EPT. We’ve divided the article into four blogs to make it easier to digest -- click here to find parts one, two and four.

Topics: varnish SVR hydraulic oil contaminination lube oil turbine oil

2 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 2 of 4

By Brad Bainbridge on Tue, Jul. 29, 2014

Combined Cycle Journal recently published an article on turbine lube oil varnish written by Peter Dufresne Jr. and his team at EPT. We’ve divided the article into four blogs to make it easier to digest -- click here to find parts one, three and four.

Topics: varnish SVR hydraulic oil contaminination lube oil turbine oil

2 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 1 of 4

By Brad Bainbridge on Tue, Jul. 22, 2014

Topics: varnish SVR hydraulic oil contaminination lube oil turbine oil

3 min read

How to Change Out a Filter Element

By Brad Bainbridge on Wed, Jun. 11, 2014

Changing a filter element can cause massive contamination ingression if the proper precautions are not taken and the proper procedures followed. We have compiled a step-by-step guide to minimize contamination ingression while changing out elements. Check out how to change out a filter element below

Topics: contaminination filter elements

3 min read

[Video] Water Contamination and Removal Methods

By Scott Howard on Mon, Jun. 02, 2014

Do you know what the 3 different types of water contamination are? What about the 4 methods to remove water from your fluid? Watch our short video for a thorough explanation of each.