3 min read

Hy-Pro Filtration Helps Paper Mill Achieve 75% Cleaner Oil

By Brad Bainbridge on Tue, Dec. 05, 2023

Topics: ISO Fluid Cleanliness Codes case study paper mill cutdirtcutcosts cleanoil

4 min read

Servo Valve Failure: A Video Case Study

By Brad Bainbridge on Wed, Jul. 10, 2019

Servo valves are a tiny but essential component of manufacturing processes. However, as you will see in the video case study below, servo valves can fall victim to failure due to excessive fluid contamination. Watch the video below to see how a tire plant in the south diagnosed and dealt with a servo valve problem that would have resulted in thousands of dollars of damage.

Topics: contamination case study servo valves

3 min read

DFE: Testing Filters Under Real-Life Conditions (Part 4 of 4)

By Brad Bainbridge on Tue, Jul. 18, 2017

Throughout the first three entries in this series (find parts one, two and three), we've discussed the difference in two filter element testing methods, ISO16889 and DFE. We've also illustrated how many elements fall short of their stated beta ratio under dynamic flow conditions. Today we'll wrap it up with simulated cold-start tests.

DFE Multi-Pass: Cold Start Contamination Retention

Once the element has captured enough contaminant to reach approximately 90% of the terminal ΔP (dirty filter indicator setting), the main flow goes to zero and the injection system is turned off for a short dwell period. Then the main flow goes to maximum element rated flow accompanied by real-time particle count to measure retention efficiency of the contaminant loaded element. The dynamic duty cycle is repeated to further monitor the retention efficiency of the filter element after a restart.

Topics: ISO 16889 case study filter performance filter elements

4 min read

DFE: Testing Filters Under Real-Life Conditions (Part 3 of 4)

By Brad Bainbridge on Tue, Jul. 11, 2017

Last week we covered the differences between the ISO16889 Filter Test Procedure and the DFE Filter Test Procedure. This week we illustrate the difference between elements engineered to retain particles during dynamic flow conditions and those that are engineered only to pass the ISO16889 test. (Looking for previous posts? Find parts one, two and four.)

Topics: ISO 16889 case study filter performance filter elements

2 min read

DFE: Testing Filters Under Real-Life Conditions (Part 2 of 4)

By Brad Bainbridge on Tue, Jun. 27, 2017

Last week, in part one, we briefly discussed how filter elements are rated by manufacturers. This week we're discussing the industry standard ISO16889 multi-pass test and Hy-Pro's standard, the DFE test. (Already read part two? Read parts three and four.)

Current Filter Performance Testing Methods

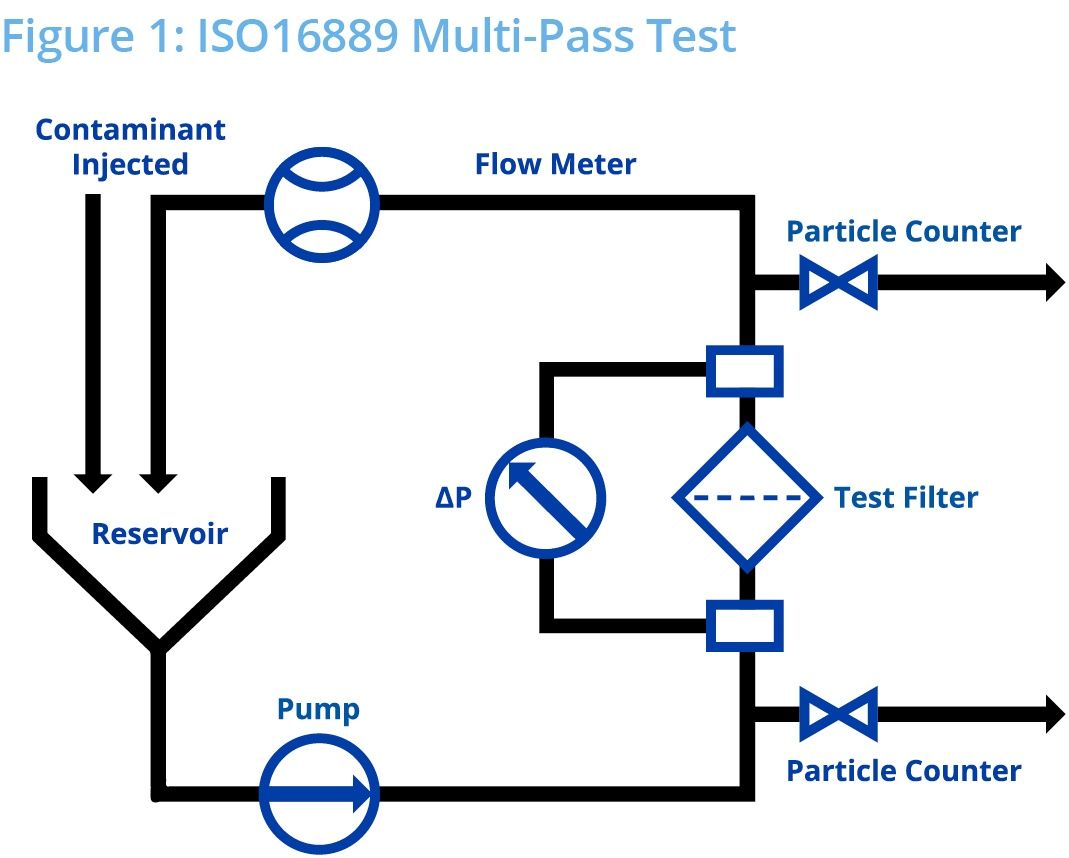

To understand the need for DFE, it is important to understand how filters are currently tested and validated. Manufacturers use the industry standard ISO16889 multi-pass test to rate filter efficiency and dirt-holding capacity of filter elements under ideal lab conditions.

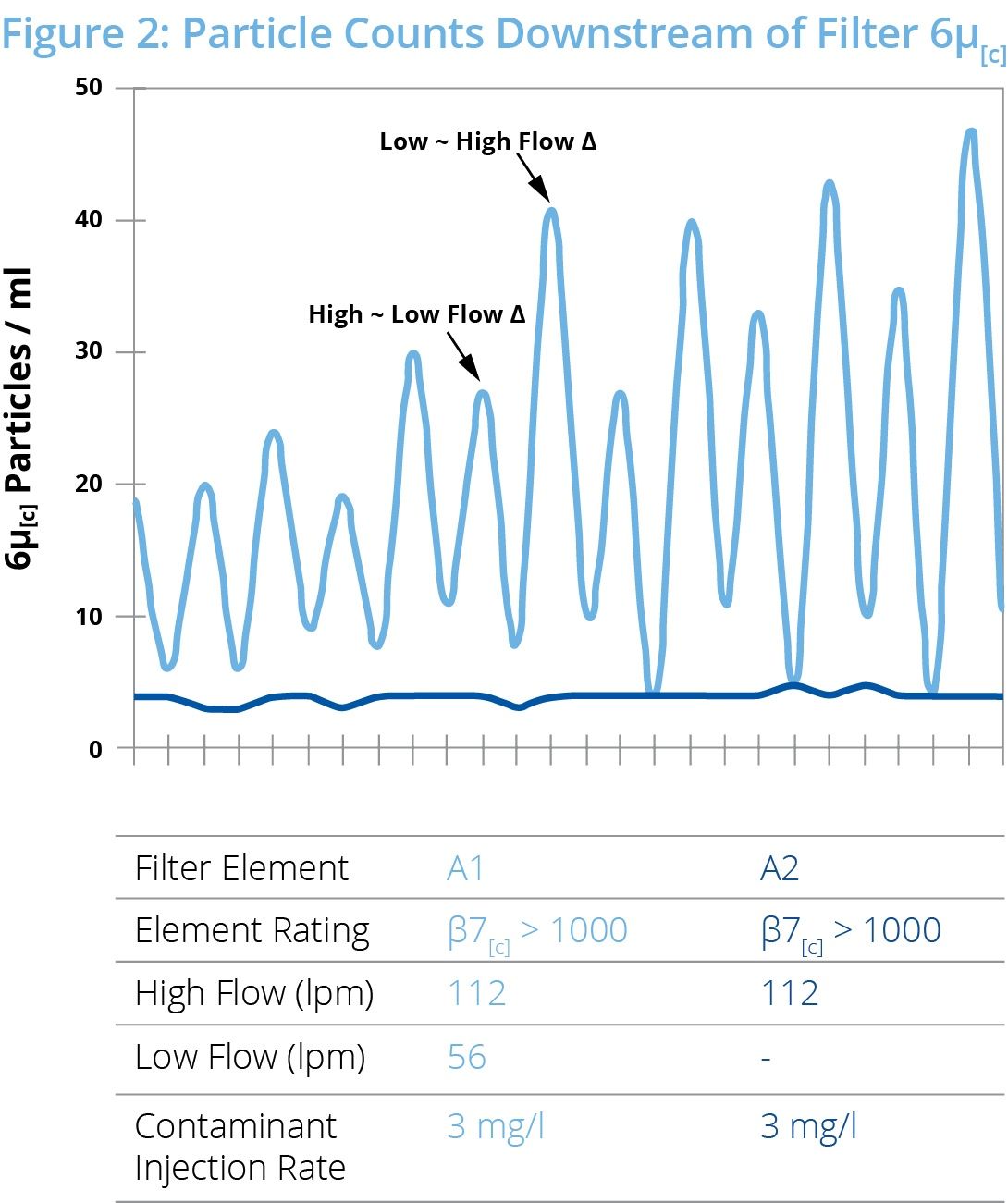

Figure 1 depicts the test circuit where hydraulic fluid is circulated at a constant flow rate in a closed-loop system with on-line particle counters before and after the test filter. Contaminated fluid is added to the system at a constant rate. Small amounts of fluid are removed before and after the

Topics: ISO 16889 case study filter performance filter elements

3 min read

DFE: Testing Filters Under Real-Life Conditions (Part 1 of 4)

By Brad Bainbridge on Tue, Jun. 20, 2017

The Dynamic Filtration Efficiency (DFE) Test is Hy-Pro's standard for testing filter elements. Throughout this four-part

First, let's start with the basics.

Why are filters used? How are they rated?

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by -- but not limited to -- the most sensitive system component such as servo valves or high-speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most out of hydraulic and lube assets.

Topics: ISO 16889 case study filter performance filter elements

3 min read

When a Pump Fails, the Whole System Fails: Hydraulic Pump Reliability

By Brad Bainbridge on Tue, Feb. 21, 2017

The Problem: Hydraulic Pump Failure

Pumps are the heart of hydraulic systems. When the pump fails, the entire system is down until the pump is operational again. This poses a serious threat to any operation relying on hydraulic systems for productivity.

Recently, a hydraulic valve manufacturer was losing 25 pumps a year on their centralized hydraulic system at a cost of $2,440 each -- and that’s only the pump cost. When you account for maintenance resources, lost oil and lost production, each failure costs ~$25,320.

Topics: hydraulic fluid ISO 4406 breathers case study hydraulic pump

7 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 4 of 4

By Brad Bainbridge on Wed, Nov. 05, 2014

Combined Cycle Journal recently published an article on turbine lube oil varnish written by Peter Dufresne Jr. and his team at EPT. We’ve divided the article into four blogs to make it easier to digest -- click here to find parts one, two and three.

Topics: case study varnish SVR hydraulic oil contaminination lube oil turbine oil

4 min read

Diesel Fuel Filtration 101

By Brad Bainbridge on Wed, Apr. 02, 2014

Reduce unplanned downtime and maximize the fuel efficiency of your diesel engines

Diesel engines are widely used today. You can find them inside buses and tractor trailers traveling our roads, humming along in construction equipment and drill rigs, submerged in marine environments and helping save lives in hospital generators, amongst many other applications. Diesel engines are popular for good reason. Not only do they have cleaner exhaust emissions, they are also known for more reliable starts

Topics: water Water Contamination diesel filtration case study contaminination

1 min read

Keeping Clean in a Dirty Environment [Case Study]

By Aaron Hoeg on Fri, Feb. 08, 2013

Mining is a dirty business, as you can imagine, and equipment used to aid in mining efforts is not immune to the filth. Yet it is imperative to keep fluid clean. Not only will it save time and money, it lessens the amount of downtime for repairs, which is always a great goal.