The Application

A hydraulic valve manufacturer required pristine fluid (< 14/12/9) to test flow across an 80-micron orifice on their test stand. Gross amounts of contamination in the fluid would skew the test results, invalidating any data collected.

The system held 100 l (26.4

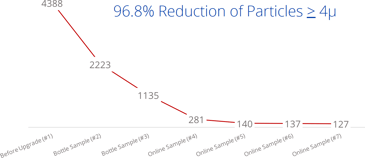

1. Insufficient Filtration

The current 12µ filter had allowed the ISO code to elevate to 19/18/16 (4388 / 2413 / 610).

2. New Oil ≠ Clean Oil

New oil was believed to be clean oil and it was not being conditioned when added to their system. New oil is not clean oil, in our experience, it usually has an ISO code around 25/22/19 (304,800 / 381,000 / 4763).

3. Bottle Sampling Practices

Observing the manufacturer’s sample collection procedures (after the filtration upgrade) revealed that the samples were being contaminated through

The Solution

Opportunities to improve fluid handling/sampling practices were identified and the onboard filtration was upgraded from a 12µ filter to a 1µ filter element (HP52NL10-1MB).

The Results

Online particle counts showed ISO codes had been reduced to 14/11/0 (127 / 16 / 0) which represented a 96.8% reduction in particles > 4µ in size and enabled the manufacturer to complete the testing of their new valve.